Getting The Snow Onto Snow Valley – A 20 Year Project Wrapped Up

From the mountains…

Did you know? Despite being in the middle of Alberta’s capital city, hundreds of kilometers from the rocky mountains, the water used to make the snow on Snow Valley comes from the mountains?

It’s true! Let me explain –

The North Saskatchewan river starts at the base of the Saskatchewan Glacier, in the Columbia Icefield, before winding its way through Abraham Lake, past Rocky Mountain House, and then flowing through Edmonton on the river’s way east. Once this water arrives here in Edmonton, it is drawn out of the river, treated by EPCOR, and is then sold to water users in the city (including Snow Valley).

It is now that the water, which started its journey in the Rocky Mountains, ends up on the Snow Valley slopes.

A pause in the water’s journey

Today, this final step is as easy as pie. Our snowmaking team connects the snow guns to one of many water hydrants on the hill, turns on the pump, and makes snow! But it wasn’t always this easy. Marlin Van Zandt, Operations Manager at Snow Valley Ski Club, has been leading the hill through an extensive snowmaking upgrade project since 2000.

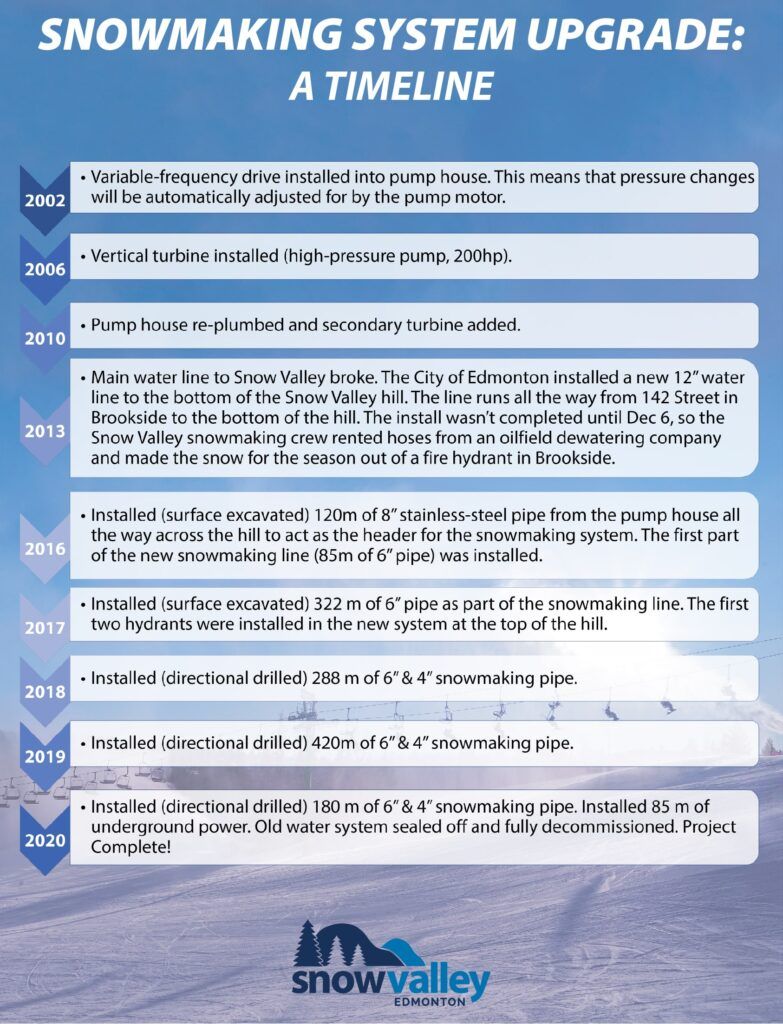

In conversation with Marlin, he outlines the overall timeline of the ski hill upgrades over the past 20 years. It started with the installation of the variable-frequency drive, and continued through the water main break and replacement, all the way to today. We now have a state of the art snowmaking system that can make snow in nearly half the time as when the first system was installed in 1984!

Our new snowmaking system makes better quality snow, faster, easier, and more efficient than ever, but there were some big obstacles on the way.

No obstacle too great

In 2013, when the water main to Snow Valley broke, the repair by the City of Edmonton took much longer than expected. So long, in fact, that Marlin and his crew had to make snow for the season using hundreds of feet of hoses, and water from a fire hydrant in Brookside! Some of our members may remember skiing down alongside the construction site that year!

When I ask about the biggest obstacle, however, Marlin answers that the approval process for the new snowmaking was a long, difficult process. It took over 5 years of discussion with the City before a new snowmaking system was approved for installation in Edmonton’s sensitive river valley.

Understandably, the City of Edmonton wasn’t going to allow the installation of any materials that would risk leaking into or damaging the river valley or the Whitemud Creek. To meet these strict limitations, Marlin sourced a newly-created pipe that met the environmental safety requirements and the project was approved.

The new water line installed under Snow Valley is made with FlexSteel Pipe, a high-tech, flexible material that was designed for, and is used heavily in, oil and gas applications.

Lines, lines, everywhere are lines

The material is made of layers of plastic laced with metal, and was chosen for two main reasons: The first of which is that it has a lifespan of over 100 years! The other reason is that, since the pipe is flexible, any small movements or seismic activity in the hill’s slope will not damage the pipes or create leaks.

Marlin also explains that the new water lines were installed 6 feet deep. This is shallower than the old system (at least 8’ deep), which means that the new lines could be installed without interfering with the existing water lines. This was crucial. Our team still needed the old system to make snow during the multi-year construction.

The entire process of installing the new snowmaking lines involved over 500 metres of trenching/excavating and over 900 metres more of water-line “pushed” through the soil without excavation, using directional drilling.

In addition to the water lines, there are also many more new hydrants and electrical outlets installed on the hill. This means that the snowmaking guns can be set up in better locations with fewer hoses and extension cords being strewn across the hill.

Reason to celebrate

Creativity, out-of-the-box thinking, hard work, and a DIY attitude made this project possible. Thanks to these efforts of Marlin and his team, the installation cost was reduced dramatically, costing only $500K (including some funding from the City of Edmonton.)

In recognition of this, Marlin received the Lars Fossberg Excellence Award in 2013. This is an industry award that is presented by the CWSAA annually “to the manager or supervisor who shows a high degree of initiative and creativity together with the ability to improvise when dealing with the unexpected. “

When I ask Marlin what his most memorable moments during the project were, he mentions 2 in particular.

The first is the installation of the variable-frequency drive in 2000. With the drive installed, the snowmaking crew can adjust valves on the snowmaking guns without having to readjust the main pump every time. This makes snowmaking way easier, and the snow quality much higher!

Marlin also mentions a memorable moment being this year – when the entire system went online. “It is great to know that this system won’t ever leak. We also don’t have to worry about water pressure or volume in the pipes. It’s great to know that the system is as efficient as we can possibly make it.” Marlin is excited that he and his team can now make better snow, with a fully safe, intact, more efficient system than ever.

…to the Sea

Once the snow is made and the ski/snowboard season gets underway, mother nature takes care of the hill, adding snow to the slopes and keeping it nice and cool. In the spring, the water melts off of the hill and flows into the Whitemud Ravine. From there, it meets up with the rest of the snowmelt in the North Saskatchewan River and carries on to Prince Albert, SK. Once in Price Albert, it meets the South Saskatchewan River (and forms the Saskatchewan River) and flows on to Lake Winnipeg before emptying into the ocean in the Hudson’s Bay.

The next time you are enjoying the slopes of Snow Valley, think of the frozen water all around you making a pause on its journey from the mountains to the ocean and think of the years of work that the Snow Valley team has put in to make it all possible!